For decades, petroleum-based plastics have been under scrutiny due to their adverse environmental impact. These synthetic polymers, widely used across industries, are non-biodegradable and a primary contributor to microplastic pollution and global waste accumulation. In response to these concerns, researchers and designers worldwide are developing innovative, eco-friendly alternatives. One such trailblazer is New York-based design lab OXMAN, which is revolutionizing the industry with its pioneering platform, O°.

O° (pronounced ‘O-Zero’) is a groundbreaking biomaterial, digital, and robotic technology platform dedicated to producing 100% biodegradable textiles and wearables. Unlike conventional materials that rely on petrochemicals and adhesives, O°-based products are crafted entirely from organic materials, ensuring zero microplastic production. This innovative digital technology streamlines traditional fabrication processes, allowing consumer products to be manufactured efficiently with minimal human intervention and almost no waste.

The first product to emerge from this cutting-edge platform is a collection of fully biodegradable shoes made from polyhydroxyalkanoates (PHAs). PHAs, a class of versatile organic materials, have long been considered a promising substitute for petroleum-based plastics. “PHAs offer an environmentally responsible alternative,” says Neri Oxman, CEO and Founder of OXMAN. “Through O°, we have developed a new technology that not only minimizes environmental harm but also nourishes the planet at the end of its lifecycle.”

Sustainable Materials and Innovations

OXMAN’s approach seamlessly integrates computational design, robotics, material science, green chemistry, and biology. Their goal is to challenge conventional industrial production systems, rethinking the very foundation of sustainable design. O° exemplifies this vision by utilizing PHAs in a way that reduces waste and pollution.

PHAs are naturally produced by bacteria that consume carbon dioxide, methane, and food waste, actively reducing atmospheric carbon levels. When disposed of, these materials decompose without leaving behind microplastics, seamlessly reintegrating with the environment. Unlike many biodegradable materials that lose durability over time, PHAs maintain integrity through regular wear, washing, and storage, making them a viable option for everyday use.

Reducing Waste Through Robotic Design

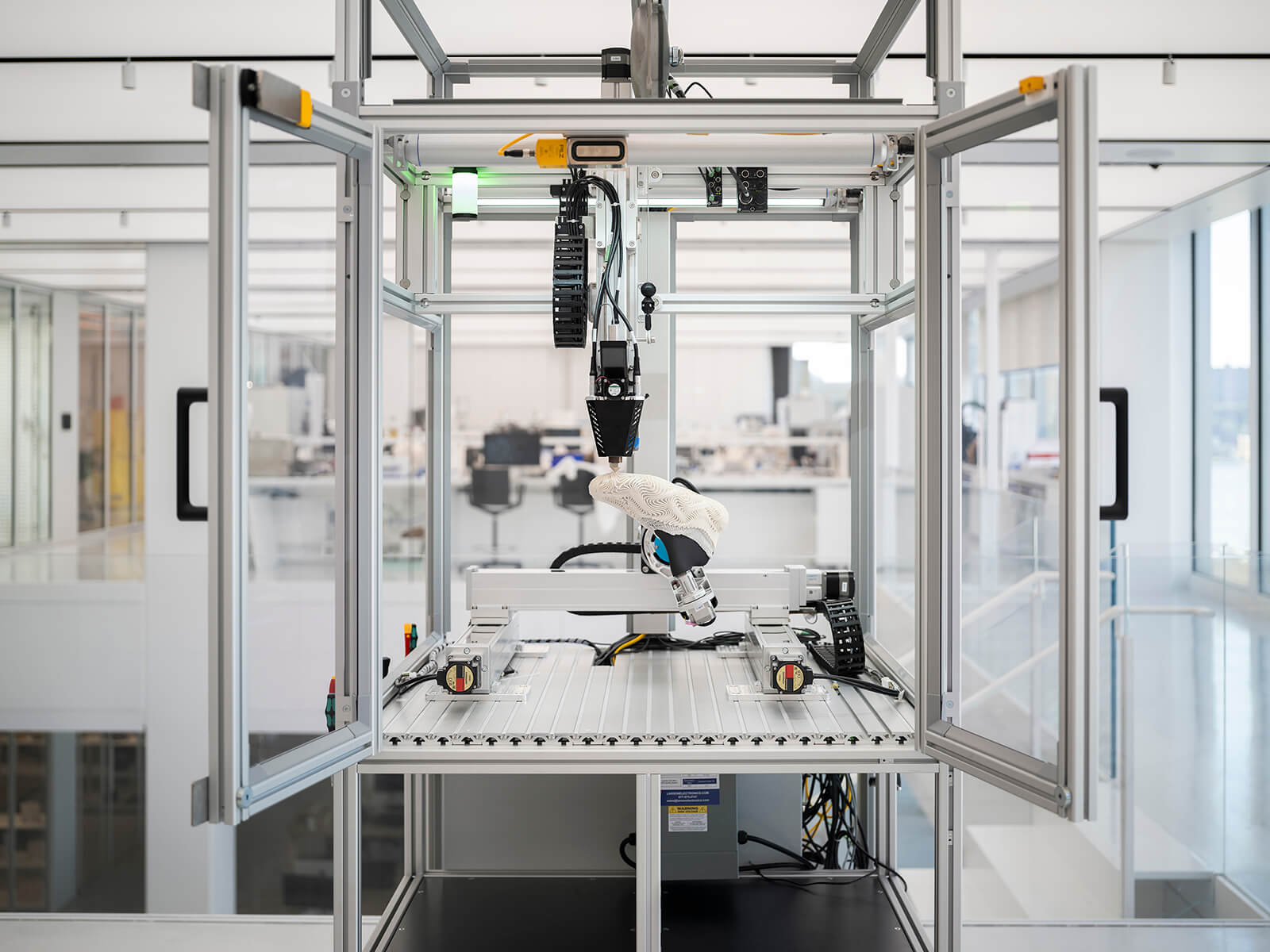

The design of O° shoes is inspired by human movement, with PHAs contributing to their versatility and adaptability. Whether designed as running shoes or ballet slippers, each piece features a knitted base layer with upper and outer layers printed onto the textile for reinforcement, cushioning, flexibility, and strength. This process allows for rapid prototyping and production while significantly reducing material waste.

At the heart of this innovation is OXMAN’s robotic system, which 3D prints custom PHA blends onto a specially knitted textile. The yarn used in the process is derived entirely from PHAs through extrusion and melt spinning. By eliminating traditional cut-and-sew and adhesive-based shoe assembly, OXMAN significantly reduces waste and reliance on manual labor. Additionally, this localized and cost-effective production model minimizes transportation-related carbon emissions, making the entire supply chain more sustainable.

Rather than relying on industrial pigments and dyes derived from petrochemicals, OXMAN harnesses bacteria to produce natural pigments. This method not only reduces dependency on complex global supply chains but also enhances the sustainability of their manufacturing process.

With the O° platform, OXMAN is unlocking the untapped potential of PHAs, reimagining the future of design and fabrication. Their holistic approach considers every stage of a product’s lifecycle—from creation to decomposition—ushering in a new era of circularity in sustainable fashion and design.

Also Read: Exploring SURFACE in Jodhpur.